Download Format Stock Opname Excel

- Download Format Stock Opname Excel File

- Download Format Stock Opname Excel 2017

- Stock Opname Persediaan

- Download Format Stock Opname Excel 2017

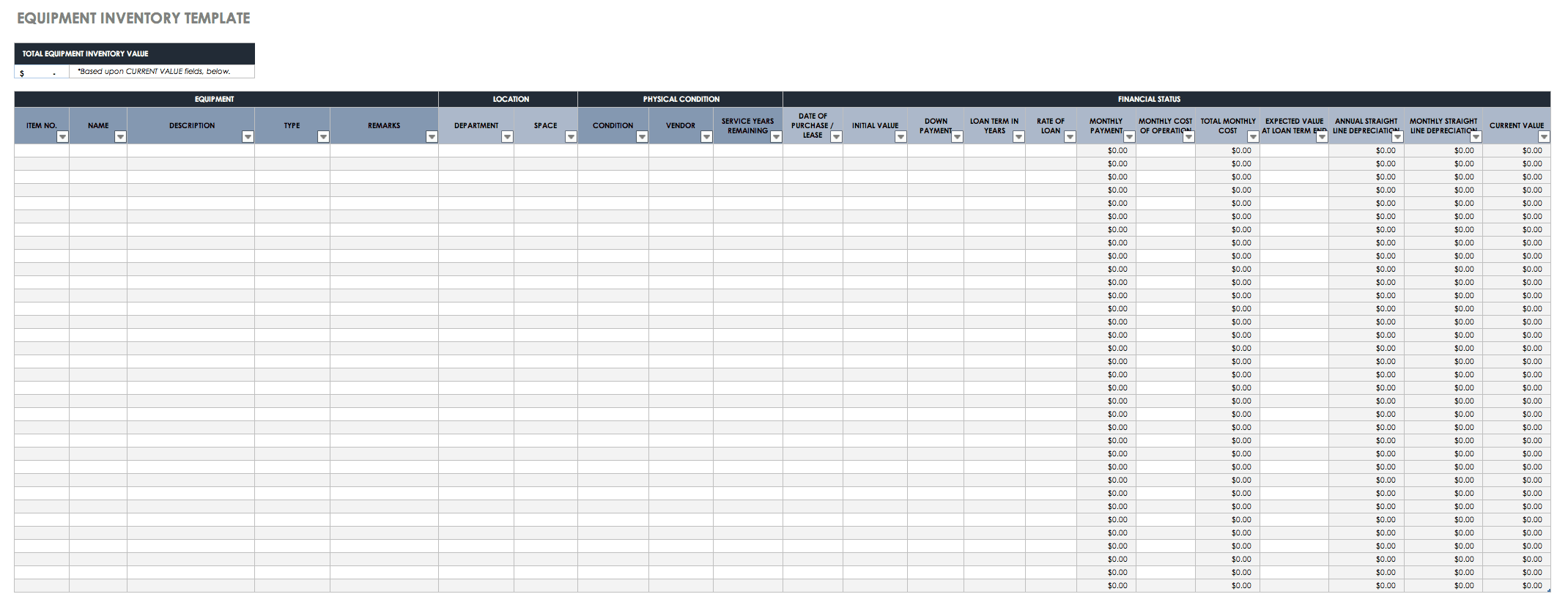

Stock card is used to show how much stock you have at one time, and how you keep track of it. There are several models of stock cards that can be created where it depends on inventory policy in your company.

Download Format Stock Opname Excel - Asyiknya buat blog saya sendiri, pada kesempatan kali ini saya akan menjelaskan kepada anda sehubungan dengan Download Format Stock Opname Excel. Jadi, jika Anda ingin mendapatkan bidikan hebat terkait Download Format Stock Opname Excel, cukup klik ikon simpan untuk menyimpan foto ke komputer Anda. Meskipun agak telat sebelOmnya saya ucapkan selamEt taOn baru bagi sOdara2, Toean2 dan Njonjah sekaliYan yang nyasar di blog ini sebagE artikel pembuka untuk tahun 2012 ini saya persembahkan aplikasi buWat ngitung persediYaan pakE excel 🙂 awalnya aplikasi ini saya buWat untuk membantu kerjaan teman yang pegang ATK di kantor udah lama bangeth. 5 Dokumen Stock opname “Lengkap”. Setiap kejadian transaksi akuntansi pasti dilengkapi dengan dokumen transaksi dengan tujuan akan memudahkan dimasukkan kedalam pembukuan dan laporan keuangan. Nah pada kasus kali ini pada Akuntansilengkap.com kita akan mempelajari tentang perhitungan fisik persediaan atau yang lebih kita kenal dengan. Sample Stock Inventory Template is a document which defines details about stock as well as essential components of stock such expiration and damage procedure. It is a delicate format with additional features and downloadable with a single click. Source: www.zervant.com. Rating 4 out of 5.

Barang gudang, stock, aplikasi, permintaan barang, atk, apk, stock gudang, stock atk, aplikasi excel, persediaan barang, aplikasi microsoft office aplikasi microsoft word microsoft office aplikasi word excel software aplikasi power point aplikasi microsoft excel membuat aplikasi dengan excel software akuntansi learn excel microsoft excel 2013 microsoft excel 2016 excel program microsoft word.

This stock card template is intended to record any items from particular supplier. By having them written in this sheet, it will make any logistic people aware about its stock quantity any time. And every time the quantity reach a minimum order level, any logistic staff can remind their superior or finance people to reorder the product.

How to Use Stock Card Form Template

In this stock card template you can write your supplier code and name and period of this log. Then you can type incoming and outgoing products based on dates. Since this sheet is set for particular supplier, the item can be set single or multi. It is up to your department policy. If it is set for multi products, you can write item codes and names, Unit of Measure (UOM), Warehouse (if more than one), purchase and sales price, number of incoming and outgoing quantity, balance quantity and important notes. You can modify these entries to more suited your inventory profile. You can delete unnecessary columns as well. And you can add more rows which it should be easy by using Microsoft Word.

Below of this stock card table, you will find stock control information that should be written with maximum, minimum and reorder level. You can add signature boxes if you think you want to know logistic people who responsible with particular stocks at any time.

Stock Card Template (17.0 KiB, 100 hits)

Other Templates

Download Format Stock Opname Excel File

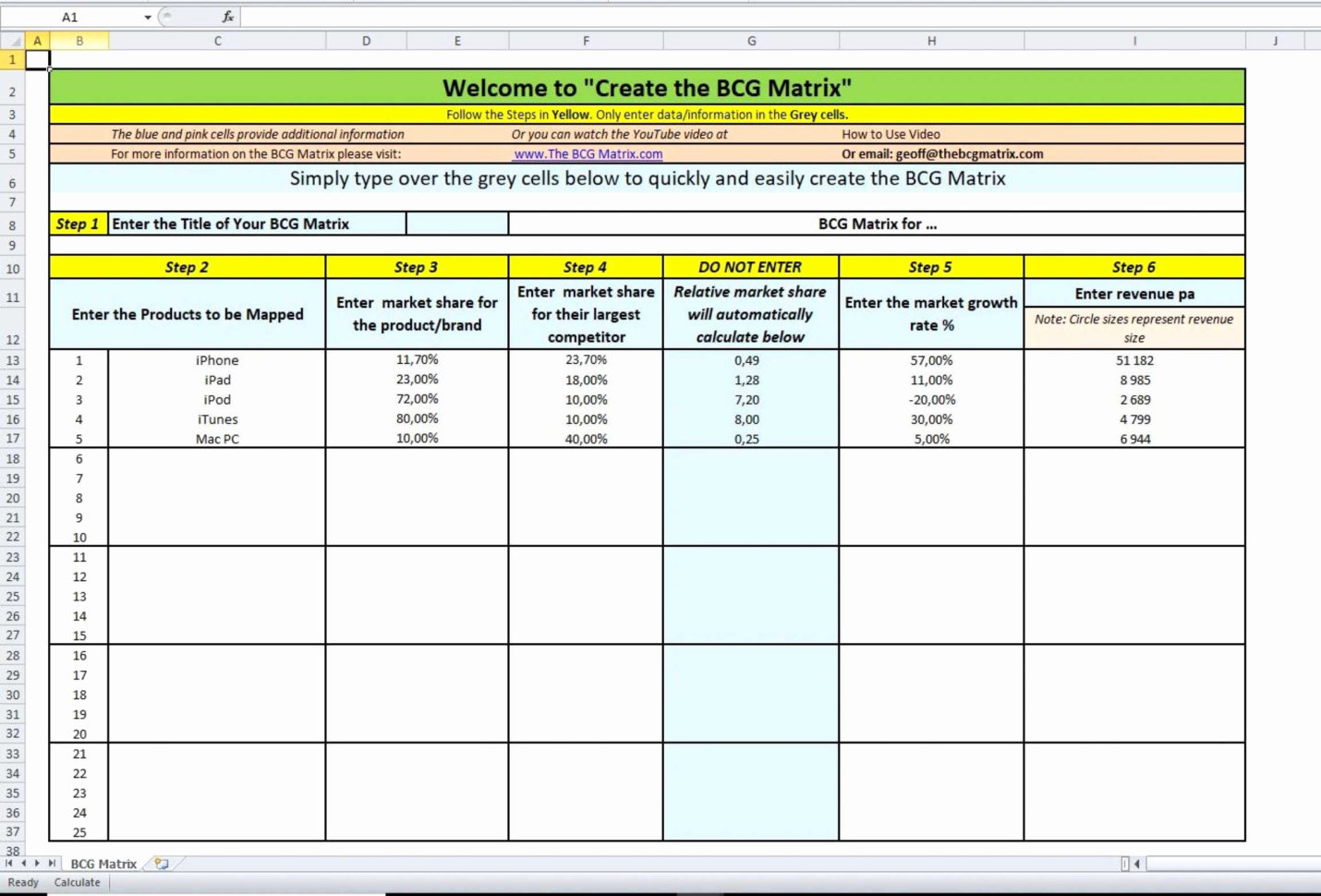

Excel template for inventory management

Votez ce document: ☆☆☆☆☆★★★★★

Excel template for inventory management

This article provides details of Excel template for inventory management that you can download now.

With these stock management models in Excel format, you can easily manage and manage your stock reserves.

These Excel inventory management examples contain several functions that are necessary already included, so that you can directly adapt them to your system.

Download Format Stock Opname Excel 2017

Microsoft Excel software under a Windows environment is required to use this template

These Excel templates for inventory management work on all versions of Excel since 2007.

Examples of a ready-to-use spreadsheet: Download this table in Excel (.xls) format, and complete it with your specific information.

To be able to use these models correctly, you must first activate the macros at startup.

The file to download presents four Excel templates for inventory management

Inventory management is the process of monitoring and controlling inventory level and ensuring adequate replenishment in order to meet customer demand. Determining the appropriate inventory level is crucial since inventory ties up money and affects performance. Having too much inventory reduces the working capital and impacts the company’s liquidity. On the contrary, having too little inventory leads to stock outs and missed sales which leads to less profit. It becomes clear that management attention should be focused on keeping inventory level somewhere in between, striving for increased customer satisfaction and minimum stock outs while keeping inventory costs as low as possible.

Service Level

The Service Level (SL) is an important performance indicator which in a simplified manner, measures a company’s ability to service customer demand and is expressed as a percentage. In inventory management, service level is the probability that the customer demand is met or that the customer demand does not exceed the inventory. A service level of 95% means that there is 95% probability that demand will be met and customer orders will be fulfilled on time, while the probability that a stock out will occur, resulting in missed sales, is 5%.The higher the Service Level, the higher the customer satisfaction but also the higher the inventory level. Since the future demand is uncertain, achieving a 100% Service Level would require an infinite amount of inventory which is clearly unachievable. Management should understand the trade-off between the cost of inventory and the cost of stock-outs and position against inventory levels based on specific criteria.

Inventory Classification

ABC inventory classification is a very popular inventory control technique that follows the Pareto Principle which states that, for many events, roughly 80% of the effects come from 20% of the causes. In a case of a business, it could be stated that roughly the 20% of the end products generates the 80% of the income. In ABC analysis, a company reviews its inventory and sorts all items into three categories, called 'A' items, 'B' items and 'C' items. A typical breakdown would possibly describe “A” items as those that produce 70% of income, “B” items as those that produce 25% of income and “C” items, as those that produce 5% of income. This classification might be different from company to company but managers should be able to find the pattern that suits best their needs. Clearly, “A” items require closer attention and should be handled differently. Assigning higher Service Levels for those items is a wise choice. The higher service level will lead to higher inventory but will also decrease the probability of a stock out. A 5% probability of a stock out for an “A” item will result to much higher losses than of a 5% probability for a “C” item. A 99% Service Level for an “A” item could have about the same impact as an 85% Service Level for a “C” item and managers should position against each category accordingly.

Stock Opname Persediaan

Forecast Error and Safety Stock

It has been already stated, that customer demand is uncertain. Managers should try to predict future demand based on statistical data and taking into account multiple criteria. It is highly desirable to try to predict the future demand and get properly prepared even with a certain degree of uncertainty than having no expectation of what is about to happen. The methods and tools used for forecasting are not under the scope of this paper. What is really important, is to find a way to calculate how closely the prediction of the demand meets the actual demand, thus how accurate a forecast is. The difference between the actual and the forecasted data is the Forecast Error. Since the Forecast Error can be calculated and not just predicted, it can be quite a safe driver for inventory management. The goal is to keep just as much inventory as it is really needed and by knowing that there is a fixed error in our estimation, we can safely take it into account and add up a bit of extra stock to our inventory to compensate for this misalignment. This is called Safety Stock and its purpose of existence is to absorb the error of the estimation and to protect the company against an unexpected and unwanted stock out. In a simplified scenario, a 30% variation of the forecasted demand should result in a 30% increase of the inventory level.

Root Mean Square Error (RMSE)

Download Format Stock Opname Excel 2017

In order to calculate the errorof a forecast the RMSE method is preferred among others, as it calculates the standard deviation of the residuals between the actual and the forecasted data. As the name suggests, the difference between the forecasted demand and the actual demand is squared and then it is expressed as the square root of the average squared residuals. In the table below, real data are presented.